The big change is going from a simple air sampler to a complete air monitoring system. The GENIUS SYSTEM is a microbial air sampling modular system, consisting of multiple satellites managed by a single software.

Unlike the TRIO.BAS RABS ISOLATOR or TRIO.BAS MULTIFLEX, which feature one command unit and a maximum of three satellites, the GENIUS SYSTEM supports more satellites with different flow rates and programs. Additionally, the command unit is replaced by a software running on a dedicated PC tablet.

GENIUS SYSTEM MULTIPLE MICROBIAL SAMPLING SATELLITE

The updated ANNEX 1 standards introduce a significant change in microbiological air monitoring. In class A and B areas, microbiological air sampling must be conducted continuously for the entire duration of the production shift.

ORUM has developed a monitoring system that meets regulatory requirements by providing flexible solutions tailored to the specific needs of end users. The platform is built on shared components and unified user interfaces, creating solutions based on the same core technology, which can be implemented across all areas. It facilitates operator activity, lowers risks, simplifies regulatory audits and calibration. It also enables data comparison across different areas using a consistent baseline.

Unlike particle sampling, which does not require an operator at the sampling point, microbiological sampling involves several steps requiring operator intervention to load, sample, and collect culture plates at the end of sampling. These tasks are risky, especially for long-term continuous sampling and when samples are spread across multiple locations. Ensuring proper coordination of these phases helps to minimize the risk of errors.

DESCRIPTION

The intelligence of the GENIUS satellite is represented by the presence on each individual satellite of a display, governed by electronics inside the satellite, which reports in real time all the phases of the sampling cycle which can be viewed and managed by the operator independently of an overall view detectable on the command console.

The GENIUS system is designed to meet the needs of market sectors where the manage of multiple microbiological sampling satellite (points) is required (such as drug production lines). Each of these satellites can be managed as part of the Genius system or, if required, can be integrated with other control instruments (such as particle counting, temperature and humidity sensors, differential pressure, air flow velocity, etc.) and therefore typically within a SCADA.

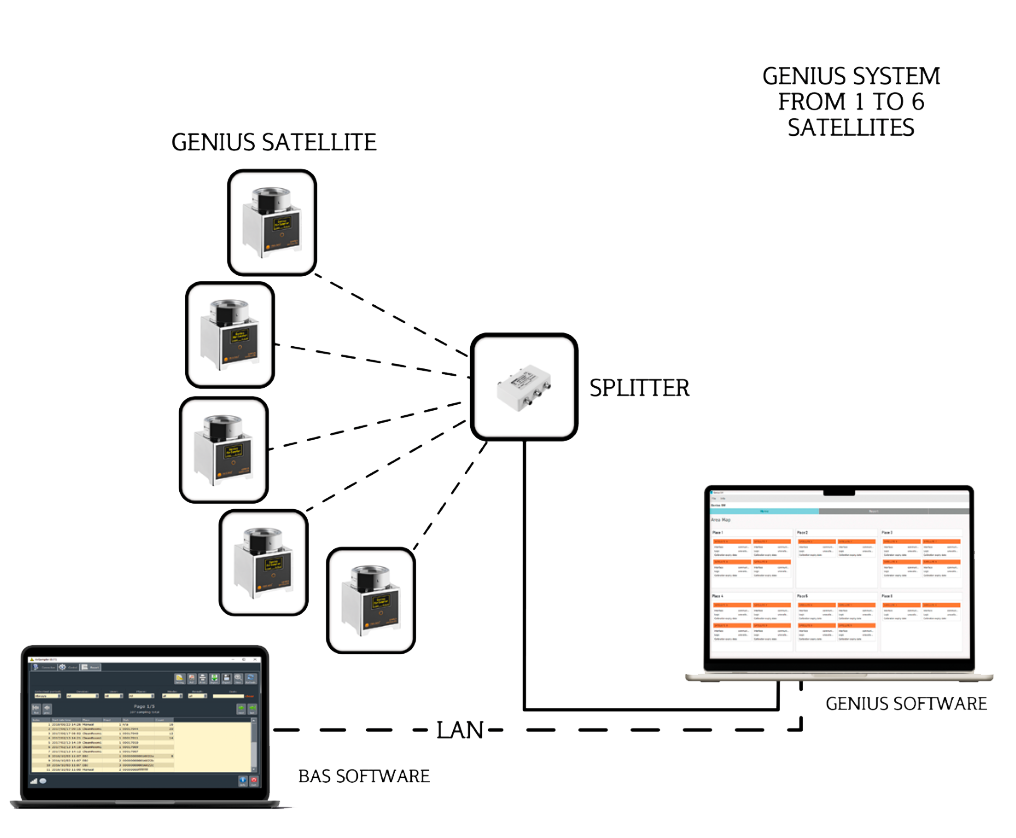

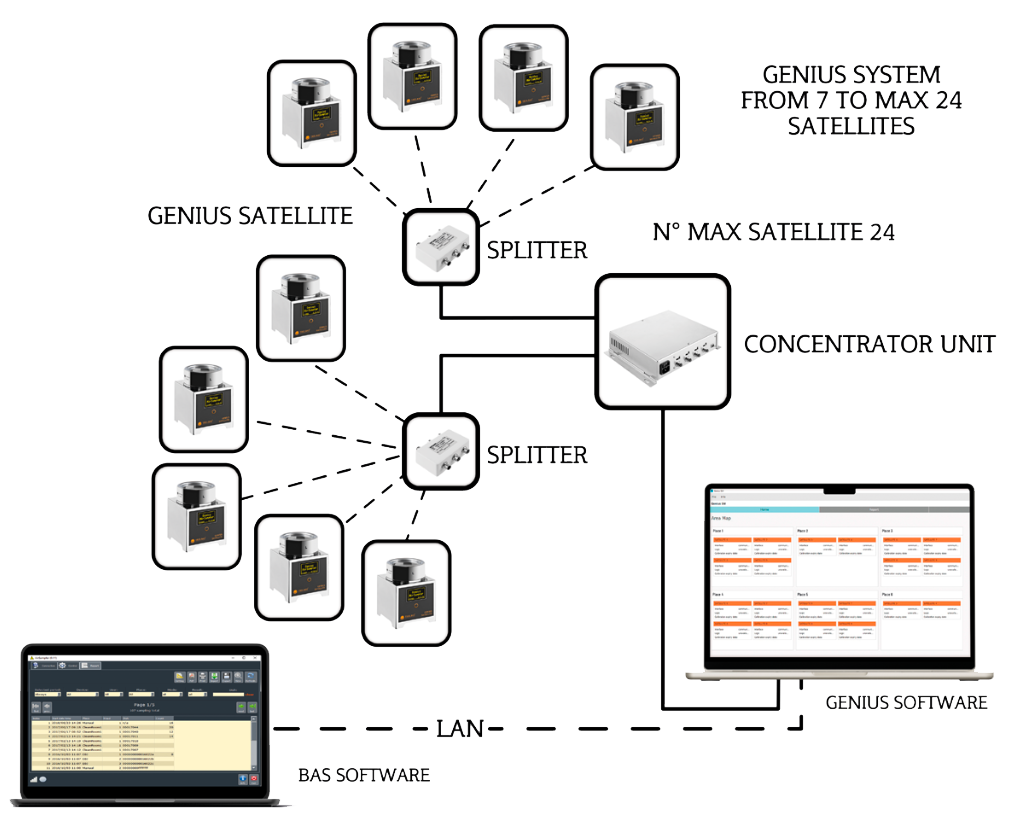

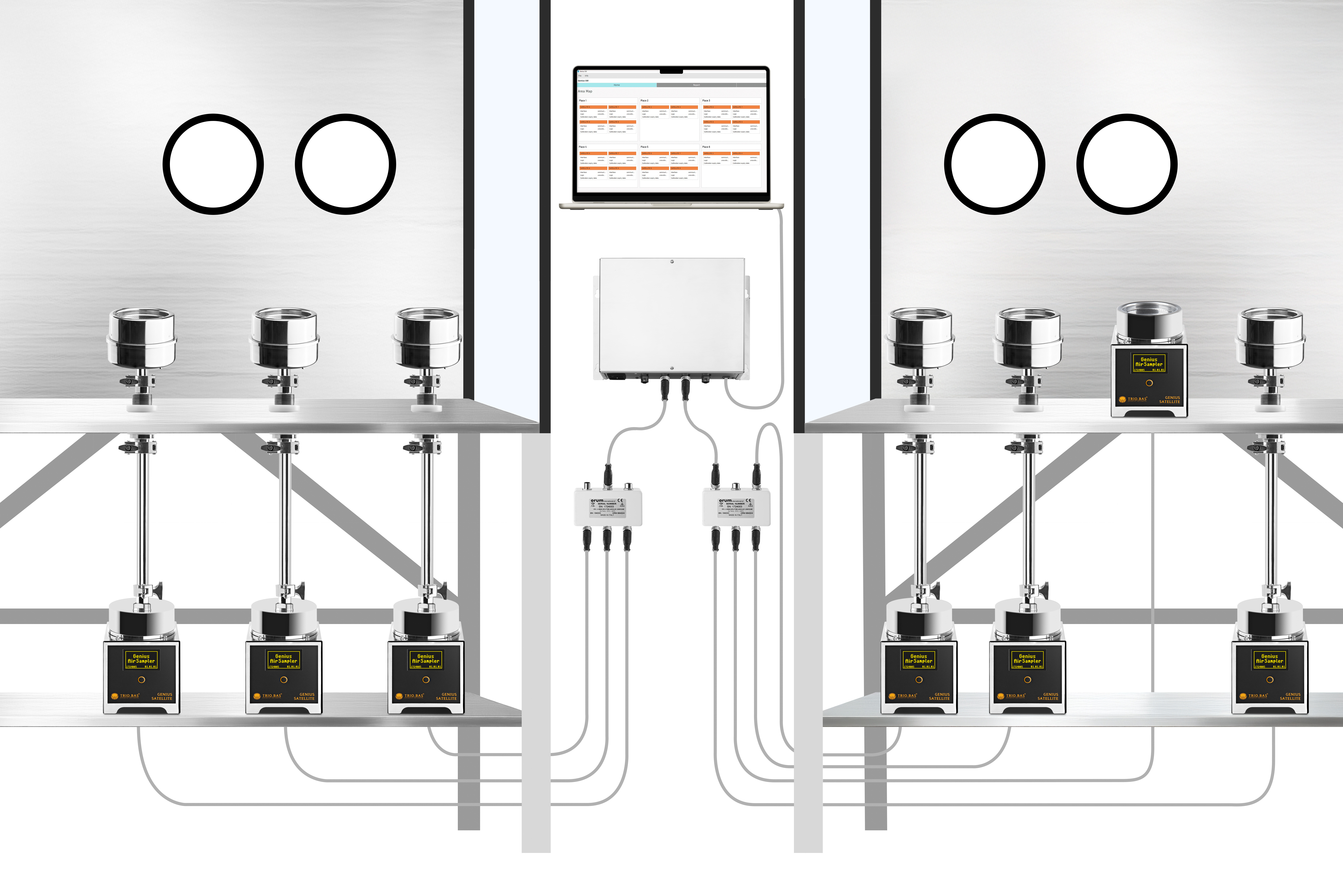

This GENIUS system allows the management of multiple satellites (from 1 to 24) via a central console command unit where dedicated software is installed and, depending on the number of satellites, with different hardware options as field interface and special adapters (splitter boxes).

ADVANTAGES

GENIUS system is the best solution:

- Low project and implementation investment.

- Simplicity and flexibility of adaptation.

- Reduced implementation times.

- Possibility of managing up to 24 satellite units with single-controlled software.

- Possibility to sample continuously for up to 3 hours using a single 90 mm Petri dish FOR EACH SATELLITE STANDARD.

- Possibility to sample continuously for up to 4 hours using a single 90 mm Petri dish FOR EACH ROTATION SATELLITE SLIT HOLES TO AGAR.

- Facilitate operational sampling activities.

- Reduce the risk of contamination.

- Significant reduction in operating costs.

Example of a Genius System with 5 satellites

Example of a Genius System with 9 satellites

4 HOURS CONTINUOUS MONITORING

PRINCIPLE

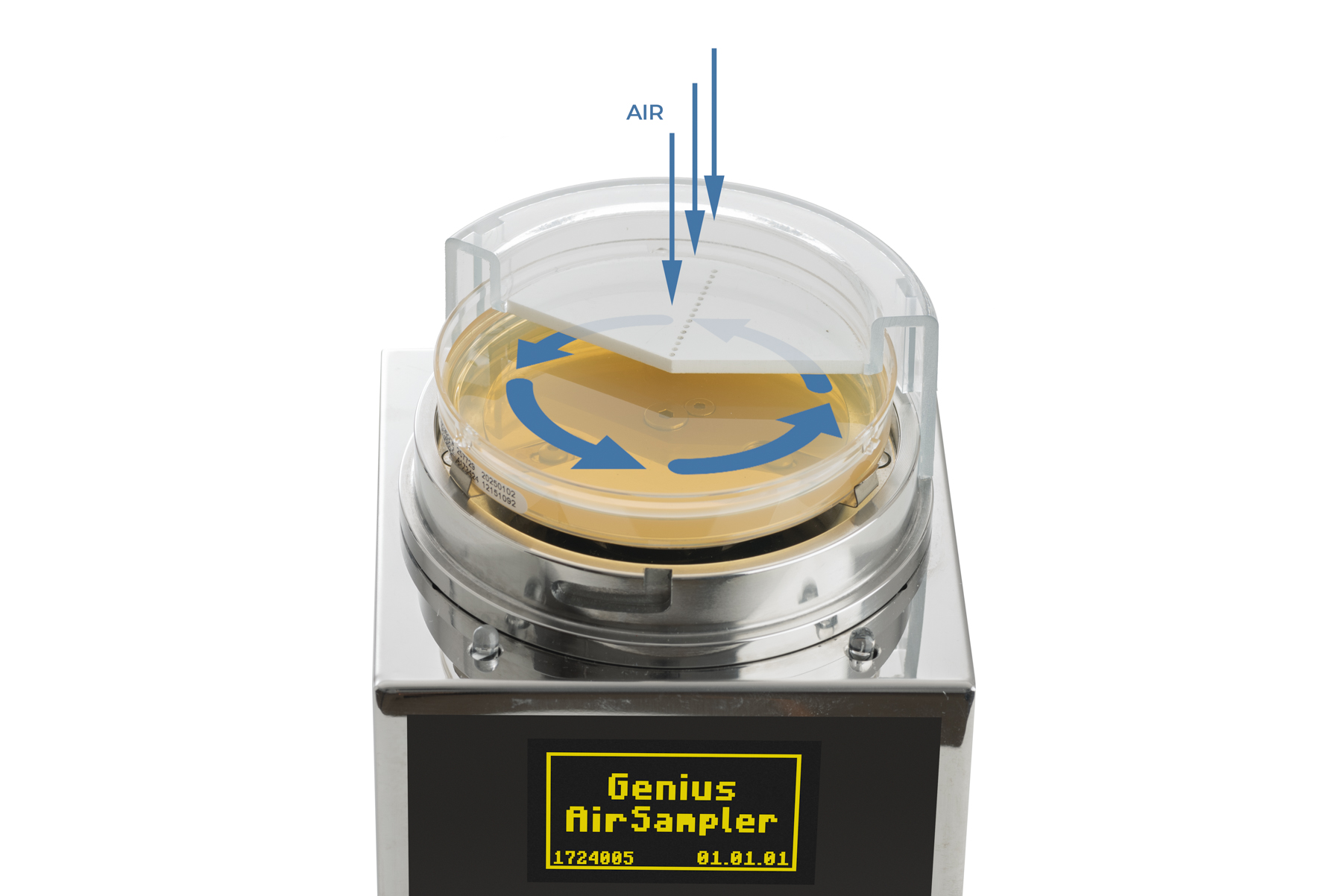

SATELLITE SLIT HOLES TO AGAR (SATELLITE ROTATION PLATE)

The air is drawn and passed at a certain speed through a single row of holes. The microorganisms present in the air impact the surface of the culture media present on a Petri dish. The Petri dish is fixed on a support below which rotates slowly. In this way the air always impacts only a virgin area of the agar.

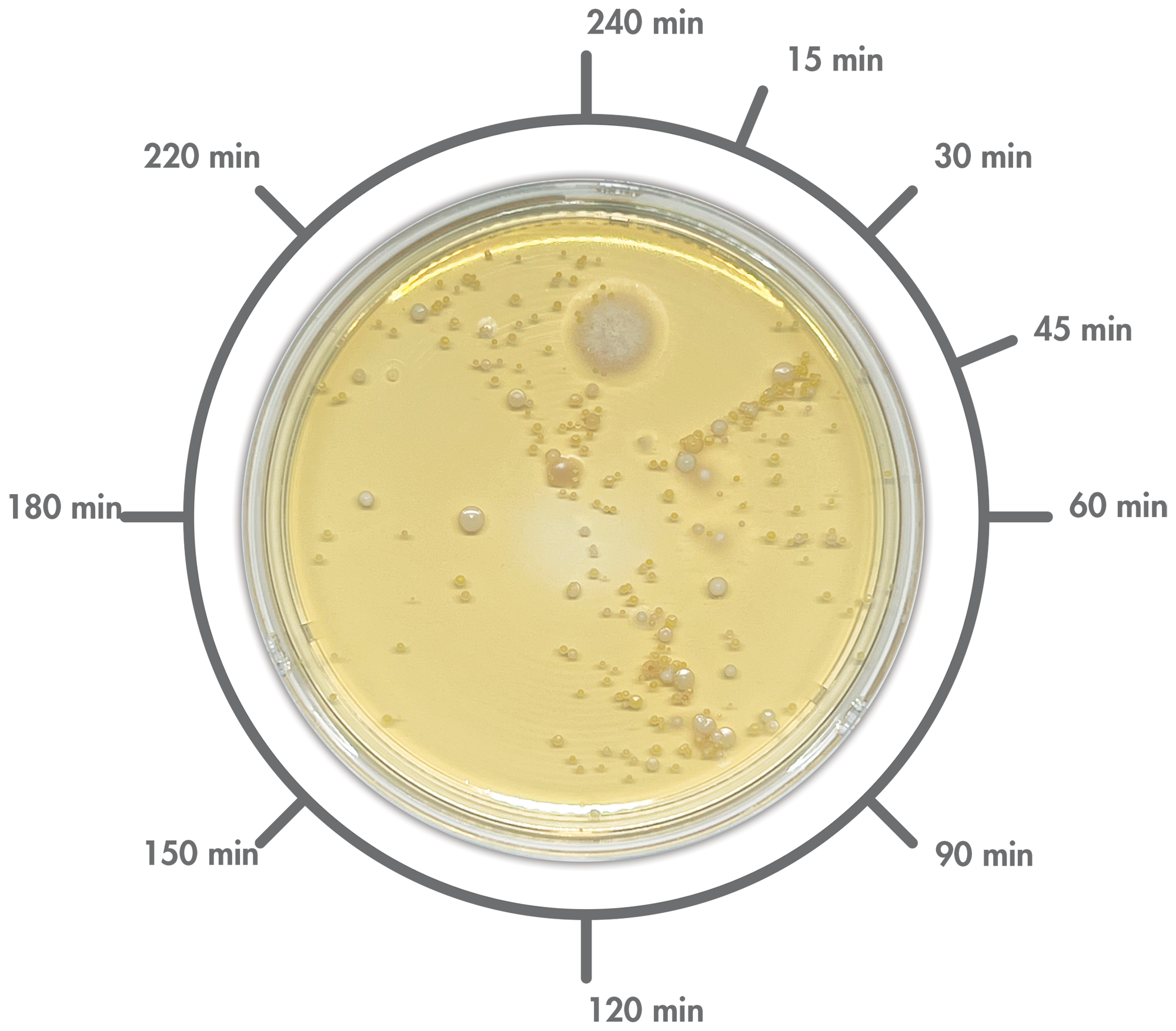

Through this principle, various advantages are obtained, including cost reduction. You can sample for up to 4 hours with a single Petri dish. There is no high dehydration of the agar. The risk of contamination is reduced as operator intervention is limited. Furthermore, it is possible to identify exactly the moment in which contamination occurred.

Flow rate 25 L/m - time max 240 minutes.

Identification of time when the microorganism collection occured

GENIUS satellite 360° slit holes to agar.

REGULATORY ADAPTATION

The instrument was designed to meet key FDA requirements for acceptable environmental monitoring, as outlined in the Sterile Drug Products Produced by Aseptic Processing Guidelines. It is fully compatible with national and international standards for environmental air monitoring: The Rules Governing Medicinal Product in The European Community Vol. IV: Guide to Good Manufacturing practice for medicinal products, 199207.

ISO EN 16498-1 and 2 Clean rooms and associated controlled environments-Biocontamination.

TECHNICAL FEATURES

GENIUS system is the best solution:

- Supply voltage: 18 – 36 Vdc

- Consumption: 30 mA

- Main connection: M12 - 4 pin male

- Data connection: Bus R485, WIFI Auxiliary

- Graphic screen: Clear OLED yellow, 34x62 mm 128x64 pixels

- Flow rate: 25 L/min

- Volumes of air recovered: from 30 Liters to 6000 Liters

- Type of plate: Petri plate 90 mm.

- Rotating plate: max 240 minutes.

- Output filter: HEPA filter H14 99,99

- Operating temperature: 10° C – 40°C.

- Humidity (non-condensing): 0 – 85%RH

- Devices manageable by a single software: from 1 to 24 satellites

- Devices that can be connected via a splitter: 6 outputs

- Splitters connectable via Concentrator Unit 4

- Maximum connection cable length: 25 m. for single satellite

- Sample sampling setup: User; Location; Plate ID; Time delay

- Complies with CFR21 regulations

- Real time data synchronization

IDENTIFICATION CODES

| Code | GENIUS SYSTEM |

|---|---|

| 869K | TRIO.BAS GENIUS SATELLITE SLIT HOLES TO AGAR - flow rate 25 l/m with s/s aspi head slit holes to agar (30 holes), s/s cover head, connection cable (5 mt) and carrying case |

| 870K | TRIO.BAS GENIUS SATELLITE - flow rate 25 l/m with s/s aspi head (180 holes), s/s cover head, connection cable (5 mt) and carrying case |

CONNECTIONS

On the back of the satellite there is a connector used to power the equipment and to connect it to the field interface or a splitter box via an RS485 serial line with Modbus RTU protocol.

There is also an atmospheric pressure measurement point which is used to control the differential pressure inside the satellite and, consequentially, the air flow rate.

The GENIUS sampling system consists of a series of "intelligent" satellites (from 1 to 24) governed by software (GENIUS SW) installed on a mobile control unit connected to the satellites via Cable, via a field interface unit and a splitter box.

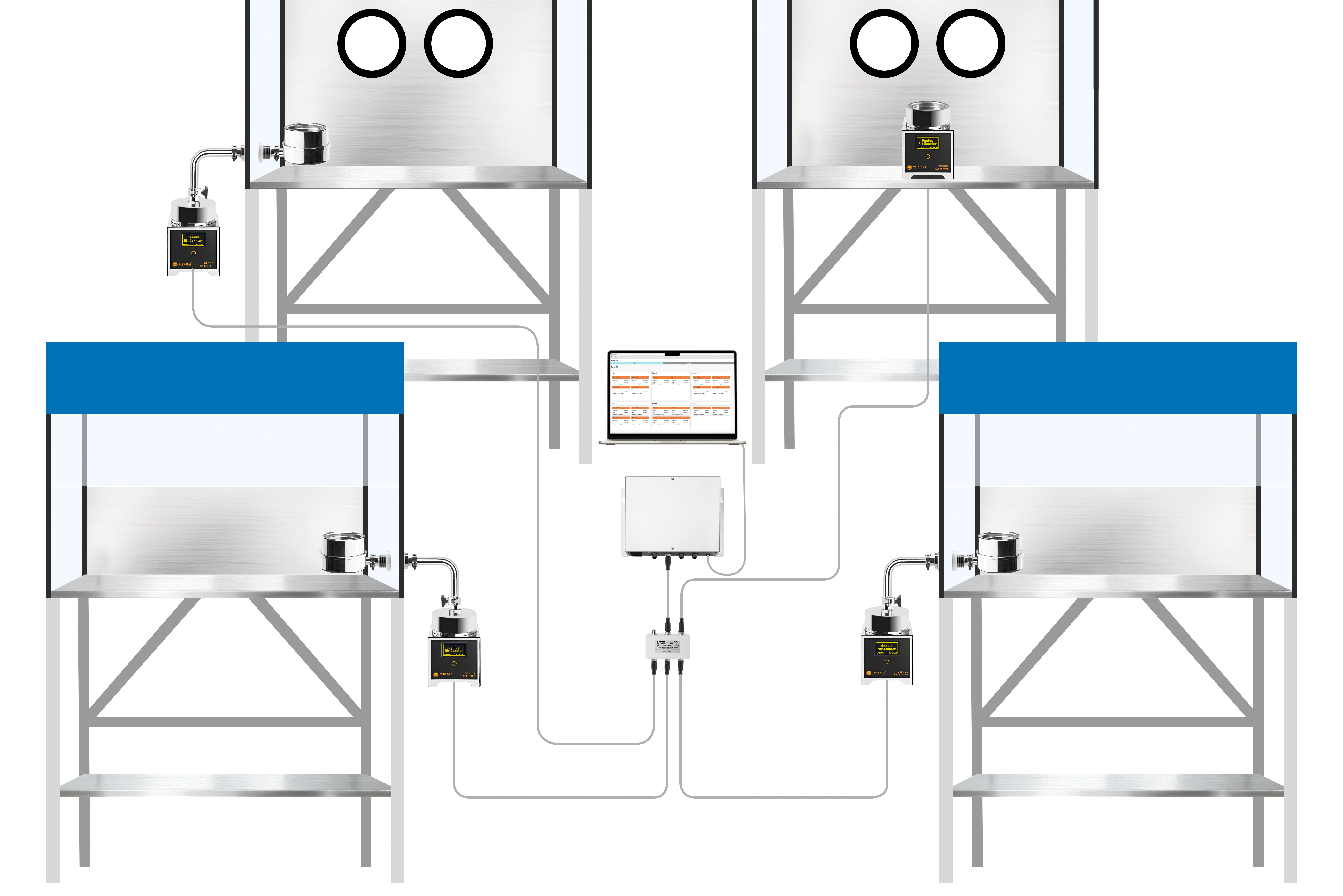

Example of a genius system installed in two separate insulators and configured with 1 standard satellite and 5 satellites with remote heads

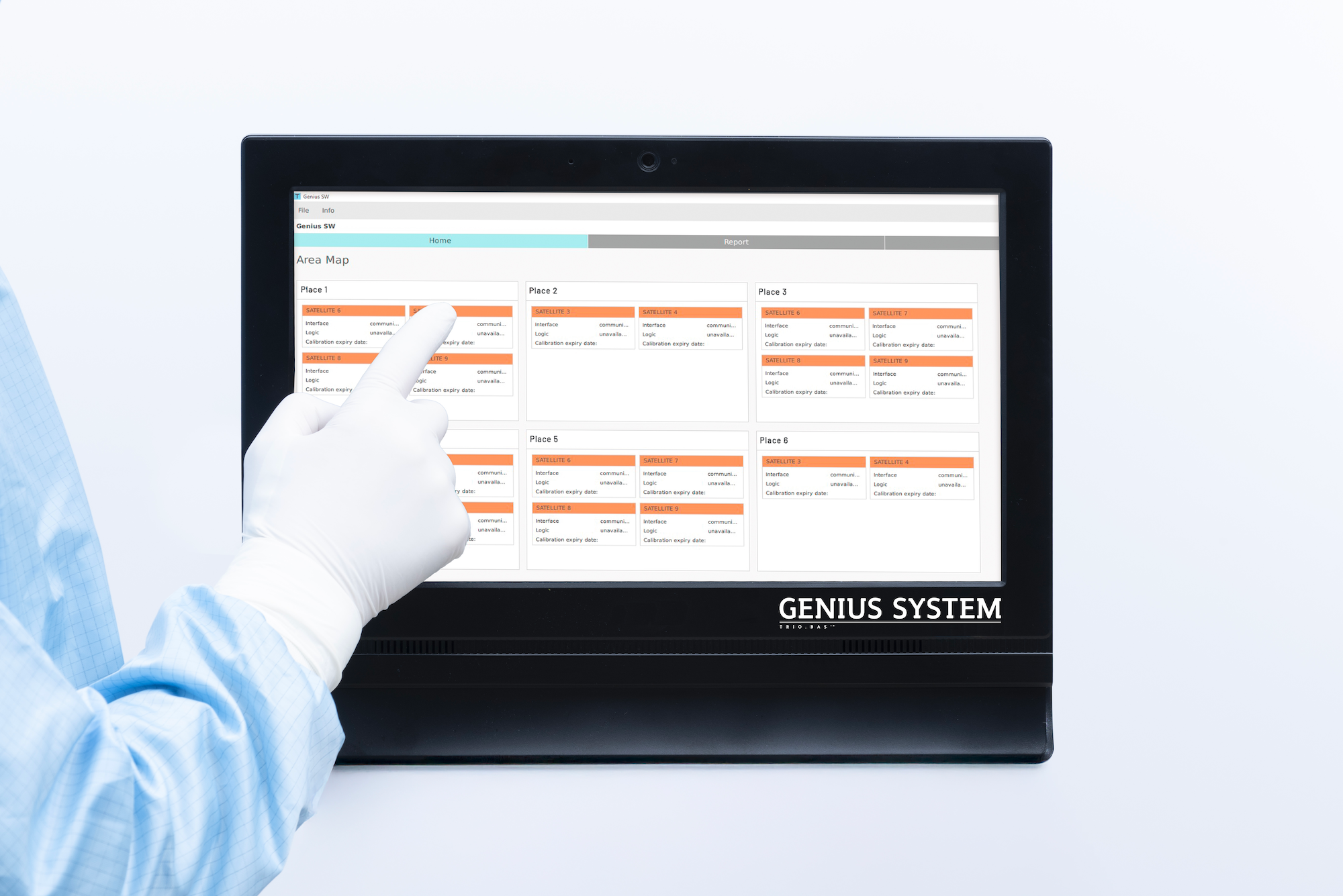

The GENIUS software is designed to manage GENIUS satellite air samplers located in different environments and sampling points. (creation of sampling lines, programming of GENIUS satellites). This software is installed on a mobile console (on Linux operating system) and allows management of the database via RS485 Modbus. It is also possible to manage user databases and related permissions.

At the end of each sampling process the related data are transferred to BAS SW and become part of the main database. In fact, BAS SW is the Orum solution for managing and storing data related to sampling processes and results, users and admin operators, locations, ...

Both software can be installed separately (mobile console for GENIUS SW and BAS SW for PCs connected to each other via cable or WIFI), in case the operational area is far from the QC laboratory.

Both software are structured to be able to manage all tools, people and data in general in compliance with the Data Integrity rules required by regulatory authorities.

In the Genius software, you can see the real-time status of each component: at rest, running, or in error.

The reports from GENIUS satellites are consolidated into the BAS SW in a single database, which also includes TRIO.BAS YELLOW and stainless-steel LINE instruments, along with advanced functions such as CFU counting and export reports.

Example of a Genius System installed in two BSF and two isolator and configured 3 satellites with remote heads and 1 standard satellite

English

English

Arabic

Arabic

Chinese simplified

Chinese simplified

Dutch

Dutch

French

French

German

German

Japanese

Japanese

Korean

Korean

Portuguese

Portuguese

Russian

Russian

Spanish

Spanish

Ukrainian

Ukrainian